Choosing the Right Lifting Equipment: A Guide for Remote Industrial Projects in Western Australia

Published by Totallifting at Mon Jun 23 2025

Industrial projects in remote regions like the Pilbara or broader Western Australia come with unique challenges. Harsh environments, limited access to suppliers, and strict safety requirements mean that selecting the right lifting and rigging equipment isn't just about convenience — it's about safety, efficiency, and project success.

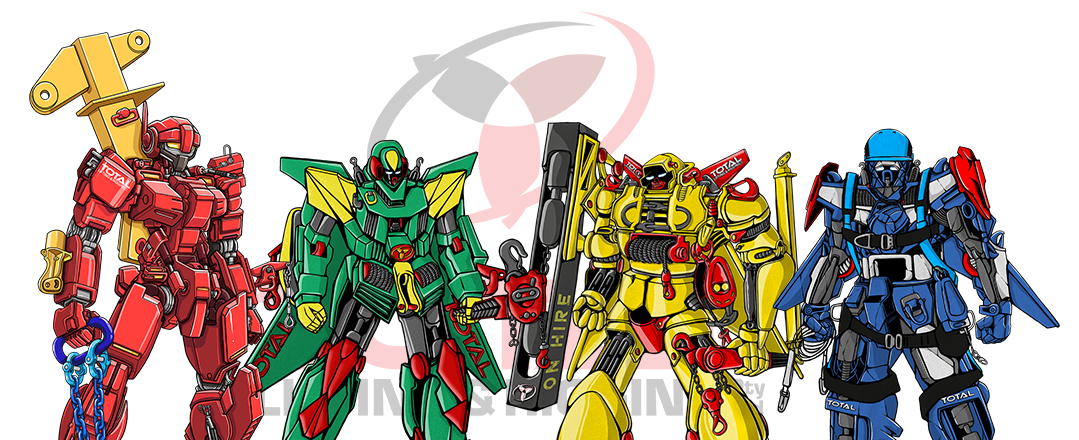

At TOTAL LIFTING & RIGGING, we understand the demands of working in remote areas. With over 80 years of combined industry experience and a base in the Karratha Industrial Estate, we’re committed to helping clients choose the right gear for their job — whether through purchase or flexible hire solutions.

Here’s your complete guide to choosing the right lifting gear for your remote industrial project.

1. Understand the Load Requirements

Before you even look at equipment, understanding your load characteristics is crucial. Ask:

- What is the maximum weight to be lifted?

- Is the load symmetrical or awkwardly shaped?

- Are there sharp edges or fragile surfaces?

Different loads require different lifting solutions. For example:

- Wire rope slings and chain slings offer durability for heavy or abrasive loads.

- Synthetic slings are ideal for lifting delicate equipment without surface damage.

- Spreader bars and lifting beams can be used to distribute weight more evenly across wide loads.

Using the wrong lifting gear can result in equipment failure or unsafe lifting practices — something no remote project can afford.

2. Evaluate the Environmental Conditions

Western Australia’s remote regions can be hot, dusty, windy, and highly corrosive — particularly near mining, marine, or offshore environments. Your lifting gear must be suited to these harsh conditions.

- For coastal or offshore projects, stainless steel or galvanized gear is better suited to resist rust.

- For high-temperature environments, certain synthetic materials may degrade faster — steel options may be safer.

- For dust-heavy worksites, equipment with minimal moving parts (and fewer maintenance needs) may be more reliable.

We always recommend choosing products that comply with Australian Standards and have been tested under extreme conditions, like those we provide with our NATA test certification.

3. Consider the Project Duration

Whether your lifting requirement is for a single lift, a multi-week shutdown, or a long-term operation, the duration of your project plays a significant role in your equipment selection.

For Short-Term Projects:

Our Hire Equipment Services are the ideal solution. Hiring allows you to access high-quality, regularly maintained gear without the upfront investment. You can also return the equipment once your project is done — reducing cost and storage hassle.

We offer a broad range of lifting and rigging gear available for short or long-term hire, including:

- Chain blocks & lever hoists

- Hydraulic jacks & pumps

- Spreader beams

- Shackles & slings

- Height safety equipment

Our expert team can assist with delivery, setup, and testing to ensure everything meets spec.

For Long-Term Projects:

Purchasing your own lifting gear may be more cost-effective. We supply globally recognised brands, and every piece comes with manufacturer and/or NATA-certified test documentation. Plus, our team will help you build a custom lifting kit suited to your needs.

4. Ensure Compliance with Safety Standards

Workplace safety is critical — especially in remote sites where access to emergency services or replacement equipment is limited. You need gear that meets or exceeds the latest safety regulations.

At TOTAL LIFTING & RIGGING:

- All lifting gear is supplied with certified documentation

- Equipment is tested in our NATA-accredited laboratory, including proof-loading on our 200t WIROP test machine

- Our team is available to perform on-site inspections, testing, and certification

- We also support height safety systems, essential for elevated or hazardous lifting environments

5. Work With Local Experts

Operating in remote Western Australia means you can’t afford long delays, poor service, or substandard gear. That’s why working with a local specialist is vital.

TOTAL LIFTING & RIGGING is proudly based in the Karratha Industrial Estate and has supported clients across mining, oil & gas, marine, construction, and infrastructure projects in the Pilbara and beyond.

Our local presence means:

- Faster delivery times

- In-person consultations and equipment advice

- On-site support and emergency backup

- An understanding of regional regulations and site-specific needs

6. Flexible Solutions That Work for You

Not every project has the same budget, timeline, or site conditions — which is why flexibility matters.

We offer:

✅ Hire or Purchase Options

✅ Custom Lifting Solutions

✅ On-Site Load Testing & Certification

✅ Scheduled Inspection Programs

✅ Access to Global Manufacturers’ Products

Our approach is to partner with you, not just supply equipment. From planning to delivery, we’re with you every step of the way.

📞 Let Us Help You Plan Your Next Remote Project

Choosing the right lifting equipment is about more than just capacity. It’s about selecting the right gear, for the right conditions, backed by a trusted local provider.

Need expert help?

Contact TOTAL LIFTING & RIGGING today to talk with our experienced team. We’ll help you design the safest, most cost-effective lifting plan for your project — whether you’re based in the Pilbara or beyond.