Inside Our 200t WIROP Test Machine: Proof Load Testing You Can Trust

Published by Totallifting at Mon Jun 23 2025

The Power Behind Every Lift

In the lifting and rigging industry, safety and reliability are non-negotiable. When lives, equipment, and infrastructure are on the line, every shackle, sling, and chain must be tested to meet the highest standards. At TOTAL LIFTING & RIGGING, we’ve invested in a state-of-the-art 200-ton WIROP test machine, giving our clients unmatched confidence through certified proof load testing. Whether you're operating in offshore oil and gas, mining, construction, or heavy industry, our testing service ensures your gear performs when it matters most.

This blog takes you inside our testing facility, explains how the WIROP machine works, and highlights why it’s a critical part of your safety and compliance strategy.

What is Proof Load Testing?

Proof load testing is the process of applying a controlled load to lifting or rigging equipment to verify its strength and integrity. It confirms that equipment can handle its rated capacity without permanent deformation or failure.

Unlike destructive testing, proof load testing does not damage the item being tested. Instead, it validates its safe working load (SWL) or working load limit (WLL), giving both operators and inspectors peace of mind.

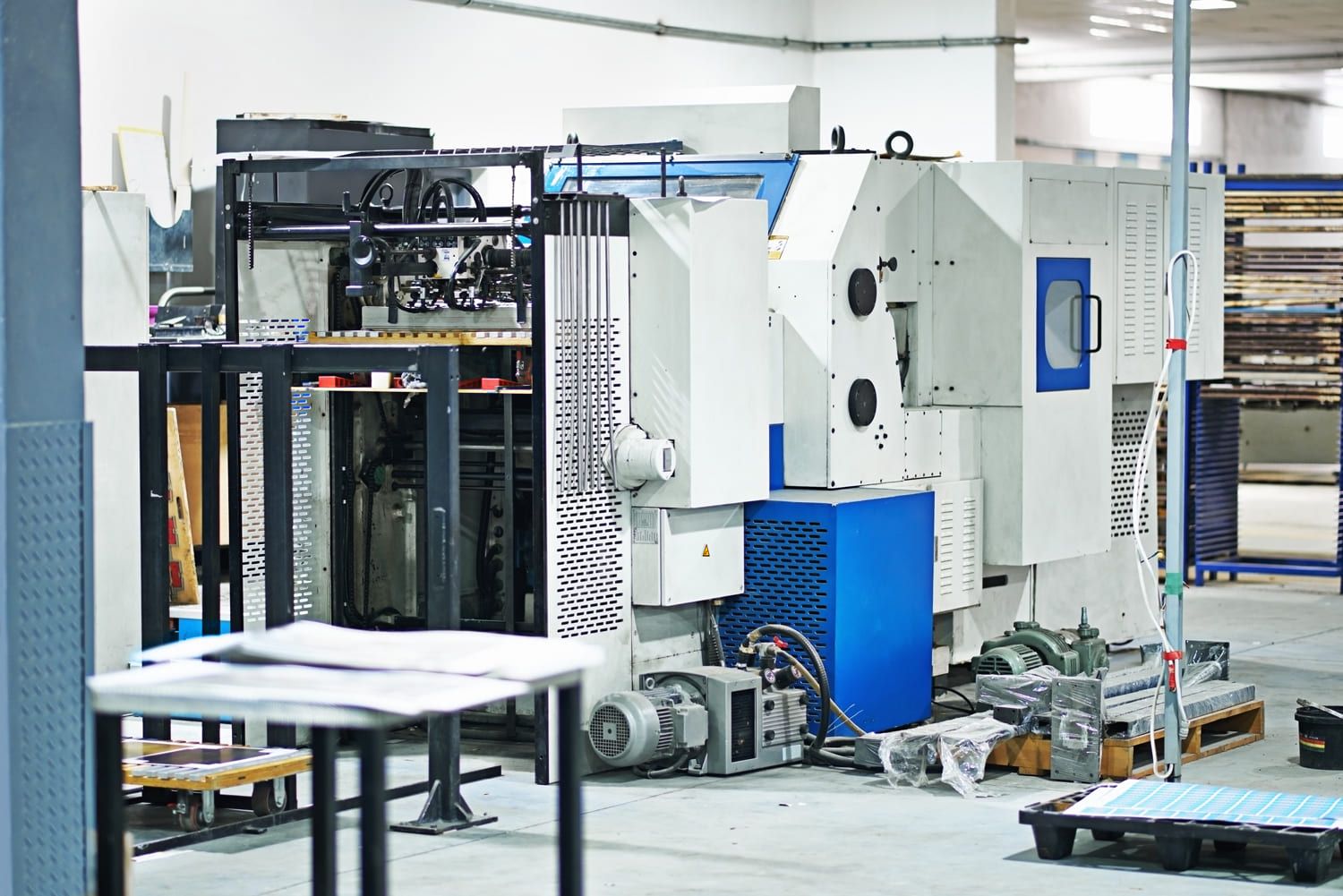

WIROP 200t Test Machine: At the Heart of Our Facility

Located in our NATA-accredited laboratory in the Karratha Industrial Estate, the 200-ton WIROP test machine is one of the most powerful and accurate hydraulic test benches in regional Australia. Engineered by WIROP Industrial Co. Ltd., a global leader in wire rope and rigging machinery, this machine allows us to test a wide range of lifting and rigging equipment, including:

- Wire rope slings

- Chain slings

- Shackles and turnbuckles

- Lifting beams and spreader bars

- Custom rigging assemblies

- And more

With a 200-ton (approx. 1960 kN) test capacity, it supports both horizontal and vertical testing, complete with precision data recording and printed NATA test certificates.

Why Proof Load Testing Matters

1. Compliance with Australian Standards

Australian regulations (AS 4991, AS 3775, AS 3850 and others) require that lifting equipment be proof load tested before being commissioned and at intervals during its service life. Our testing services meet or exceed these standards, and as a NATA-accredited provider, our certification is accepted nationwide.

2. Risk Reduction

Load testing detects hidden faults or weaknesses—before they lead to catastrophic failures. Our inspection team ensures every weld, connection, and lifting point passes a detailed inspection under real-world stress conditions.

3. Insurance & Legal Protection

Should a workplace incident occur, proof of recent, certified testing can be critical in meeting your legal obligations. TOTAL LIFTING & RIGGING issues complete documentation, traceable to each component tested.

4. Asset Reliability

When your lifting equipment is regularly tested and certified, you can depend on it for critical lifts, reducing unexpected downtime and costly delays.

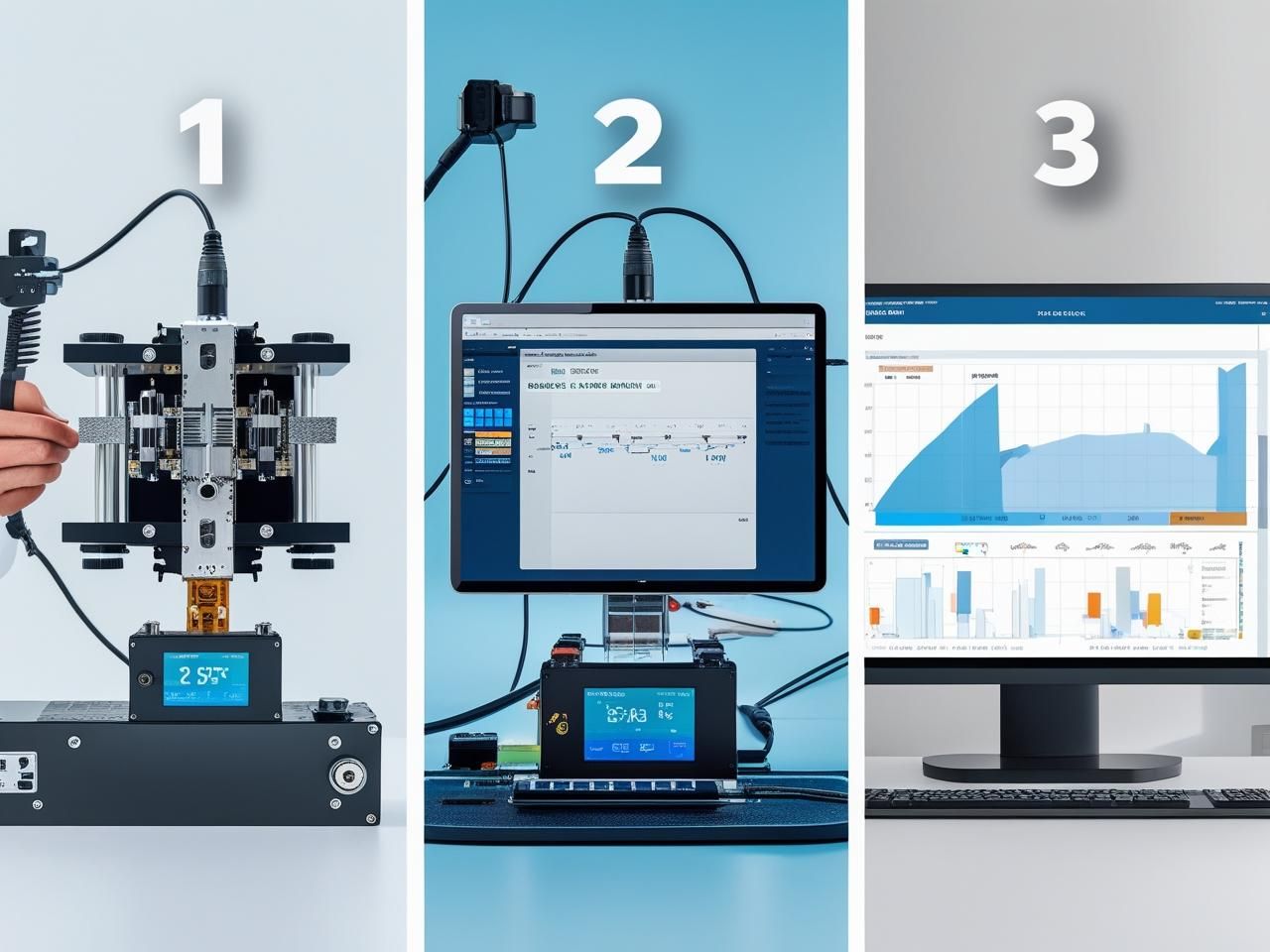

The Proof Load Testing Process: Step by Step

Step 1: Equipment Identification & Visual Inspection

Each item received is inspected visually for signs of wear, corrosion, or damage. Manufacturer details and serial numbers are logged into our system for traceability.

Step 2: Mounting on the WIROP Test Bed

The item is securely mounted on the test bed using the appropriate fixtures. The test configuration is adjusted based on the type of equipment and test specification (e.g., tensile or compression).

Step 3: Controlled Load Application

Using hydraulic pressure, the load is applied gradually while sensors monitor deflection, elongation, or any abnormal response. The equipment must withstand the proof load (usually 1.1 to 1.5 times the rated working load) without permanent deformation.

Step 4: Data Capture & Certification

Real-time data is captured throughout the test. Once passed, a NATA-certified test report is issued with load graphs, item details, and test technician verification.

Step 5: Equipment Release or Rejection

If the item passes, it is tagged, labeled, and ready for use. If not, it is quarantined for repair or disposal depending on the condition.

Who Should Use Our Load Testing Services?

Our clients include:

- Mining and resource companies

- Construction contractors

- Marine and offshore operators

- Industrial maintenance teams

- Equipment hire firms

If your operations involve lifting heavy loads, you need verified, tested, and documented rigging equipment—and we provide exactly that.

Why Choose TOTAL LIFTING & RIGGING?

✔ 80+ Years of Combined Experience

Our team includes industry veterans who understand lifting standards, safety, and operational pressure.

✔ Local Expertise in Pilbara

Based in Karratha, we serve the Pilbara region with fast turnaround and on-site pickup/delivery options.

✔ NATA Accreditation

We are accredited to ISO/IEC 17025 for mechanical testing—your guarantee of quality and reliability.

✔ End-to-End Solutions

From supplying top-tier lifting gear to testing and inspections, we’re your one-stop partner.

Real Results: WIROP Testing in Action

We recently worked with a mining contractor needing urgent testing for their custom spreader bar. Our WIROP machine completed the 150t proof test with full certification in under 48 hours, allowing the project to stay on schedule and avoid crane downtime.

Schedule Your Next Load Test Today

Whether you’re commissioning new gear or recertifying existing equipment, TOTAL LIFTING & RIGGING is ready to help. Our WIROP 200t test machine provides the most reliable proof load testing in Western Australia—backed by NATA certification, detailed reporting, and world-class customer service.

✅ Contact us today to book your test

📞 Call: +61 8 9143 1511

📧 Email: sales@totallifting.com.au